Case Studies

NEW Case Study

A beverage manufacturing facility in is expanding its process to South Korea and beyond its current capacity. They are concerned about the purity of the CO2 that will be coming in contact with products and the possibility of contamination.

A craft brewery was growing and the amount of CO2 they were using was increasing. They wanted to ensure the quality and sterility of the CO2 that they are using throughout their facility and safety of their brewing process.

Open Fermentation” means the tanks would have an opening at the top to allow for access for air into and out of the tank. This process allows the wort/beer to breath naturally throughout the fermentation process achieving more complex taste

Culinary Steam

The Success of the Micropure culinary steam filter in this facility was so drastic compared to the steam filter they had prior, the client has replaced every steam filter in its facility with a Micropure Culinary Steam filter and is currently working on replacing all of the steam filters in its other facilities Nationwide.

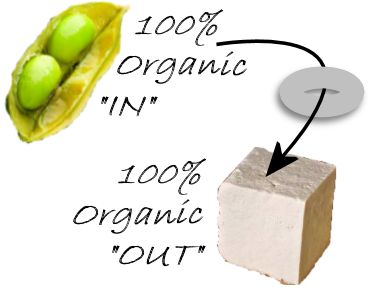

Being able to call your product 100% organic requires more than just organic ingredients. It requires an organic process, including filtration.

By redesigning the PDF multi-round filter Micropure was able to supply was a larger housing that would be able to fit multiple elements inside each housing.

Parker Finite Products

A US based advanced security and detection systems company based tackles the worldwide threat nuclear weapons being moved through shipping containers.

Steam Filters

Micropure presented them with a proposal for a 100 micron Steam filter that was sized specifically for their application. This will act as a pre-filter to the current culinary steam filters they have in their systems.

The Micropure steam filter has many advantageous features for breweries. Each media piece works independently allowing for maximum filtering capacity and extremely low pressure drop.

Sterile Gas/Air filters

With a 24/7 production schedule every minute counts. The need for a low/consistent pressure drop, inline/multiple sterilizations, and quick/easy media replacement led to the Sterile Air Filter

A craft brewery was growing and the amount of CO2 they were using was increasing. They wanted to ensure the quality and sterility of the CO2 that they are using throughout their facility and safety of their brewing process.

Because of the major budgetary limitations Micropure recommended the use of its PSF-0604 “Mini” Filter. The Mini filter has a few differences from the standard PSF filter model but worked great for the application.

SulfurGuard

A beverage manufacturing facility in is expanding its process to South Korea and beyond its current capacity. They are concerned about the purity of the CO2 that will be coming in contact with products and the possibility of contamination.

The patented SulfurGuard CO2 filtration system puts the process gas through several phases to ensure the post filtered CO2 is 100% sterile, free of any possible contaminants and safe for use in soft drink carbonation.

Tank Vent Filters

Open Fermentation” means the tanks would have an opening at the top to allow for access for air into and out of the tank. This process allows the wort/beer to breath naturally throughout the fermentation process achieving more complex taste

When a clients filters were clogging too quickly the engineers at Micropure went to work investigating the problem. The culprit ended up being pretty sweet.

The client has a large tank farm as a part of its new facility with over 75 tanks. There were several major concerns 1. filter life, 2. operational cost, 3. pressure drop at installation and throughout the life of the filter.