Mash Filter Press |

Mash Press Presentation |

Filter Press consisting of a series of cloth filters fixed to frames, used for the large-scale filtration of liquid under pressure. |

Rake system and False bottom that are common in commercial lauter tun |

20 HL Mash Press as Part of HEBS Brewing System. Feed and Return piping is present in foreground |

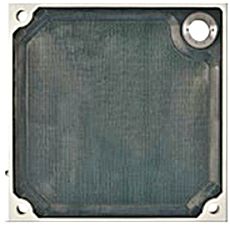

Mash Filter Membrane Plate made from solid polypropylene with Black EPDM bladder. |

What’s a Mash Filter?

A mash filter press is a large frame filter used for filtering mash. The mash goes through the same basic steps as a traditional lauter tun. The mash is pumped into the filter. The mash slowly fills up each chamber. Once the chambers are filled to capacity, a squeezing process begins to help remove wort and extract from the mash. Pressure from the mash and squeezing process will push the wort through a micron rated filter cloth before the wort gets pumped to the next phase.

Why use a Mash Press?

In a traditional brewery, a lauter tun is used to remove the wort from the mash & grains. A lauter tun removes the extract via gravity and circulation. In the lauter tun there is a false bottom with a screen. The mash falls to the bottom of the tank and is circulated by a rake. Mash build up on the bottom creates a filtration medium. This allows the solids and liquid (clear wort) to separate.

Why is the Mash Filter Press more effective?

Time Savings

- Produce a brew every two hours

- Simple, easy cleaning in between batches

Durable Materials of Construction—Stainless Steel and Polypropylene

- Mash and Wort only come in contact with FDA approved materials.

- Skeleton made of enamel coated carbon steel. Enamel coating is FDA approved.

- Save CAPEX costs by using carbon steel frame.

Savings of Raw materials

- Use of 10%-20% less grain

- Use 20%-40% less water

- 20%-40% combined overall raw material, energy and labor cost savings.

- Use of Malted and unmalted grains and cereal (up to 50% less cost)

Technical Advantages

- Achieve up to 98+% extract

- Produce faster conversion with fine stripping mill (up to 20% flour)

- 20%-40% combined overall raw material, energy and labor cost savings.

- Flexible System that allows for multiple brew styles

- High Degree of Automation Expandable system

Advantages of Membrane Filter Plates

Shorter Filtration Cycles

- The squeeze feature of the membrane plates allows you to shorten your cycle time between loads

Lower Residual Moisture in Cake

- By using feed and squeeze pressure, you dramatically reduce the amount of moisture in the cake. This makes the waste load from your press smaller lighter.

Lower pressure to be used on plates

- By adding the squeezing of the membrane plates, you do not have to run your filter press feed pressure as high as in a standard membrane press.

Higher Volume per Chamber

- By Squeezing the mash, you have the ability to fit more mash into the system then with a traditional press.

Shorter Filter Press Frames

- Membrane filter presses have deeper chamber depths allowing you to have less chambers per hectoliter compared to a non-membrane filter press.

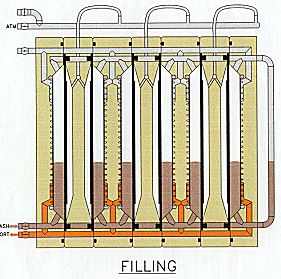

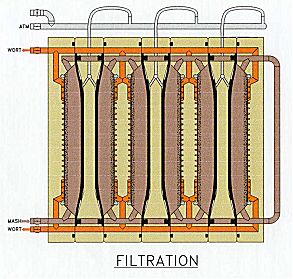

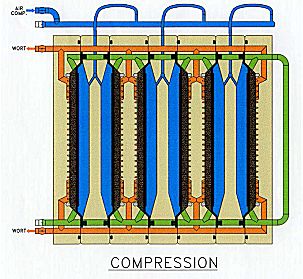

Phases of Mash Filter Press Cycle

Filling: Mash enters the chambers through a feed pump in the upper right corner. Mash will fill each chamber sequentially. |

Filtration: Once the chambers are full, the mash that is being pushed by the feed pump will force the liquid out from the chambers. |

Compression: Once the Feed Pressure has cycled out, the system will be closed and the membrane squeeze will begin. |

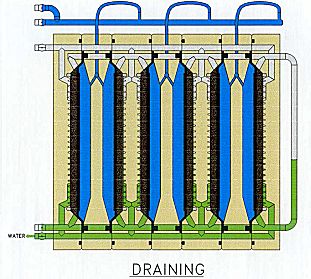

Draining: As the Squeezing is happening, the liquid will be forced out of the chambers and into one of the 3 return pipes. |

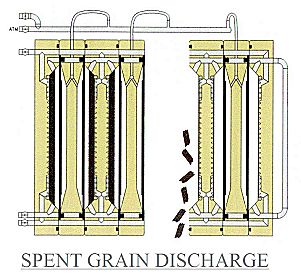

Grain Discharge: The hydraulic closure of press is opened. Each chamber is opened up for cleaning and grain discharge. |

Repeat

|

Technical Specs

| Maximum Feed Pressure | 100 psig |

| Maximum Squeeze Pressure | 100 psig |

| Maximum operating temp | 200°F/121°C |

| Mash Press Sizes | 1 HL-200HL |

| Pore Sizes | 0.5 um – 200 um |

| Material of Construction: | |

| Frame | Carbon Steel |

| Filter Plates | Polypropylene |

| Membrane Bladder | EPDM |

| Filter Cloths | Polypropylene |

Mash Press Presentation and Explanation

Articles of Interest:

- Case Study: Brewing Up a Good Solution: Choosing a brewing production system is a difficult task. It needs to handle a wide variety of beers in a short period of time, have short cleaning and cycle time, be environmentally responsible, and have a low operational cost.