Sterile Gas Filter, Culinary Steam Filter, Sterile Air Filter, and Liquid Filtration

Ideal filters for food, beverage, and pharmaceutical process

To ensure you receive the filter right for your requirements we:

- Take the time to consult with you to thoroughly understand your project.

- Analyze your application to provide a custom engineered filter specific to your needs.

- Provide a cost effective long lasting solution you will be able to use for the entire life of the unit.

- Guaranteed – because of our high quality material and segmented disc housing, you never need to worry about element warping due to heat or pressure!

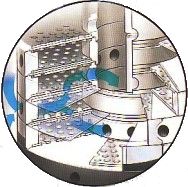

MicroPure Segmented Filters sandwich self-sealing filter media between specially designed segments of stainless steel, clamped securely by a stainless steel tension rod connecting the end segments to form the cartridge.

What this means for you

Air/gas or liquid flows into openings in the outside of a segment and passes through the filter medium into an adjacent segment which then exits through openings at the center of the cartridge and out of the filter housing.

Air/gas or liquid flows into openings in the outside of a segment and passes through the filter medium into an adjacent segment which then exits through openings at the center of the cartridge and out of the filter housing.

The number of segments and the type of filter medium used in each Segmented Filter are customized for your application.

Throughput can be significantly increased by adding segments and filter media.

Unlike conventional filter cartridges, the two-way MicroPure design provides equal support for the filter media in both directions so you can reverse the flow if your application requires.

Micropure Filtration uses

Articles of Interest:

- Case Study: The Ebb and Flow of Brewing Yeast: A liquid yeast producer is adding several new tanks and process lines it is important that the air going in to start the fermentation is sterile, as well as the air transfer during filling and emptying.

- Case Study: Brewing is Big Business: A craft brewery was growing and the amount of CO2 they were using was increasing. They wanted to ensure the quality and sterility of the CO2 that they are using throughout their facility and safety of their brewing process.

- Case Study: Sterile Vents for Tank Farming: The client has a large tank farm as a part of its new facility with over 75 tanks. There were several major concerns 1. filter life, 2. operational cost, 3. pressure drop at installation and throughout the life of the filter.

- Filtration Article: SulfurGuard Filter Time Interval Explanation: information about our filter series and a simple explanation for how we come up with our time intervals for filter element replacement.

- Case Study: Your product is only as good as your steam, and your steam is only as good as your filter: The Success of the Micropure culinary steam filter in this facility was so drastic compared to the steam filter they had prior, the client has replaced every steam filter in its facility with a Micropure Culinary Steam filter and is currently working on replacing all of the steam filters in its other facilities Nationwide.

- Case Study: Finding a sustainable solution with steam: The Micropure steam filter has many advantageous features for breweries. Each media piece works independently allowing for maximum filtering capacity and extremely low pressure drop.

- Case Study: CO2 safety is number one with Sulfurguard: The patented SulfurGuard CO2 filtration system puts the process gas through several phases to ensure the post filtered CO2 is 100% sterile, free of any possible contaminants and safe for use in soft drink carbonation.

Read More Case Studies Here

Distributor:

- Distributor of Parker Finite Filters

- Distributor of Sulfur Guard™ Filters

- International Distributors >>