Finding a sustainable solution with steam

The Client:

The Client:

World Wide Brewing Company’s original facility in the western US. The company has grown from its one site brewery to having brewing facilities on every continent in the world. This facility is one of Micropure’s original clients and has used Micropure filters since its inception in the late 80’s.

The Problem:

The brewery was installing a new production and bottling line in the facility. They want to ensure the quality of their process and the longevity of their equipment. There is use of steam throughout the line for heating tanks as well as cleaning valuable equipment.

The Process:

The Engineers at Micropure reviewed the specific application and needs of the client. Micropure presented them with a proposal for a steam filter that was sized specifically for their application. The steam filter was designed and sized based off the pressure and flow rate of the steam line. The clients chose to use a steam filter with a 32 micron absolute rating for general protection. The 32 micron Steam filter was chosen because its placement in the system and where steam was used in the process. The steam did not come in contact with any product or surface that touches that product. This allowed them to use a 32 micron filter instead of a culinary grade steam filter.

The Solution:

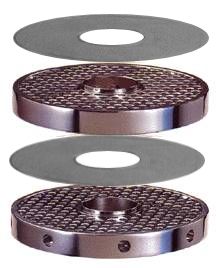

As a result of using the Micropure Steam filters, they have ensured the quality of the steam used in their production and bottling line. The Micropure steam filter has many advantageous features for breweries. The filter offered complete system security. Micropure’s filtration Media is a woven stainless steel media that has an absolute rating for steam applications. Each media piece works independently allowing for maximum filtering capacity and extremely low pressure drop.

As a result of using the Micropure Steam filters, they have ensured the quality of the steam used in their production and bottling line. The Micropure steam filter has many advantageous features for breweries. The filter offered complete system security. Micropure’s filtration Media is a woven stainless steel media that has an absolute rating for steam applications. Each media piece works independently allowing for maximum filtering capacity and extremely low pressure drop.

Besides their familiarity with the products, the clients chose Micropure because it is the economical choice. The segmented element design allows you to replace only the filtration media instead of the entire filter element. This saves money because of the small cost of the media pieces. The media can handle 150 cleanings allowing it to last a long time before it is needed to be replaced. The long life and low replacement costs make the operational costs of this filter extremely low.

The success of the filters in their installations increase the trust that the client has with Micropure Filtration and the quality solutions it can offer for steam filtration, process quality and equipment protection.